Effective stock control isn’t about counting what you have in your inventory. It’s a strategic tool that can optimize operations.

Whether you’re a small business owner, implementing robust stock management practices is essential. Here are five strategies that can help you master your stock control system. Read on to learn more.

Understand the ABC Analysis

Applying the ABC analysis (Always Better Control) is a fundamental strategy. This is to classify inventory items into three categories based on their value and usage.

Category A

Items are the most valuable, representing about 20% of stock but accounting for 80% of value. These items need tight control and greater focus.

Category B

Items fall in the middle, both value and usage. They must moderate control efforts compared to A items.

Category C

Comprises items with low value but high inventory count. This often makes up 50-60% of stock with 5-15% of total value. C items need minimal control, usually restocked as needed.

Effective supplier relationships are instrumental to smart asset control. You can achieve more favorable terms by fostering strong connections with your suppliers. This will ensure consistent supply quality and negotiate better prices.

What Are The Strategies For Effective Stock Control System Management?

There are multiple effective inventory management strategies which will optimize the warehouse. This also increases the accuracy and efficiency which will give your business an accuracy. Below I am going to discuss the strategies for effective stock control system management.

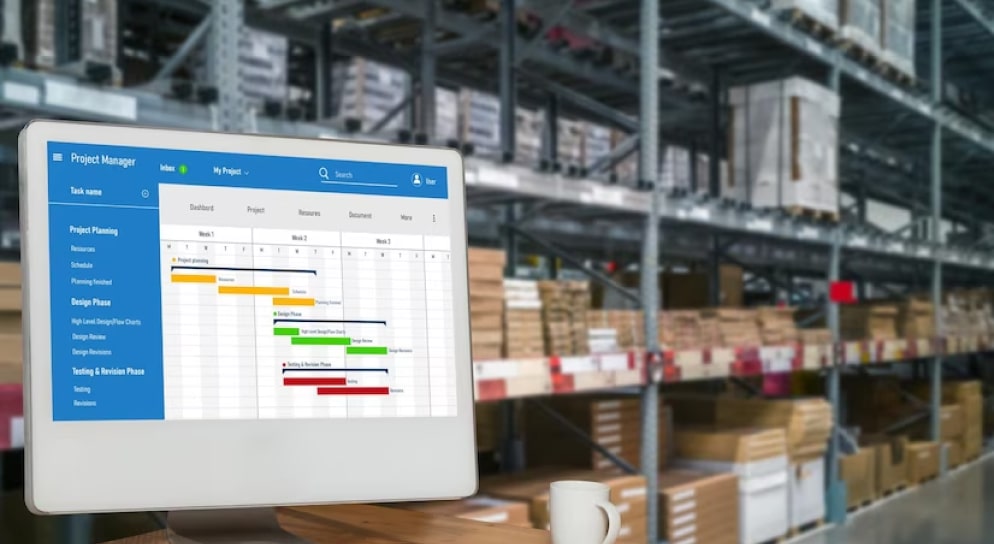

1. Install An Inventory Management System

A scalable inventory management system (IMS) is crucial to controlling inventory levels and reducing and maximizing cash flow. Track stock movement in real-time. Set up the least and greatest stock levels to trigger reordering.

Calculate reorder points using historical data and sales forecasting. Streamline the receiving and picking process. When choosing an IMS, consider these factors:

- Scalability to grow with your business

- Integration with your current systems

- Interface for quick adoption by your team

2. Optimize Stock Levels For Efficiency

Stockouts and overstocks can be detrimental to your business. The key is to find the sweet spot where carrying costs are minimized.

Conduct regular demand forecasting to understand sales patterns and seasonality. Determine safety stock levels to buffer against variability in demand and lead times. Install a just-in-time (JIT) inventory system for high-demand items with predictable lead times.

Use economic order quantity (EOQ) to calculate the optimal order quantity. It minimizes the total inventory costs.

3. Focus On Lean Inventory Practices

Lean inventory practices help reduce waste and improve efficiency. Implementing a kanban system to signal when to replenish stock. Reviewing and categorizing slow-moving or obsolete inventory for clearance sales or donations.

Encouraging vendor-managed inventory (VMI) for key suppliers to hold and manage the stock. Using cycle counting to review and correct inventory discrepancies.

4. Review And Adjust Your Strategies

Stock management is a dynamic process. You must review and adjust your strategies to align with your business goals.

Conduct quarterly or annual reviews of ABC analysis to reclassify items. Stay up-to-date with industry trends and best practices in stock business management.

Leverage technology to automate repetitive tasks. This will provide data-driven insights into your inventory performance.

Request feedback from your team and customers. This is to identify areas for improvement and innovation. You’ll be well on your way to effective stock inventory control that adds value to your bottom line and enables sustainable growth.

5. Understanding The Stock Control System

In conclusion, mastering the art of a stock control system is an ongoing journey. It requires attention to detail, strategic planning, and continuous improvement. They are an optimized operation, increased profitability, and higher customer satisfaction.

They are within reach for businesses that commit to these best practices and stay attuned to the changing dynamics of inventory management.

6. Automate Your Inventory Management Systems

Automated stock management systems are more efficient than manual stock managing and more precise, productive, and time-saving. On the other hand, by automating their stock management, business proprietors can cut expenses while reducing errors and increasing system efficiency.

7. Use Data and Analytics

Another strategy for effective stock system management is to use data that will enable business owners to always have accurate product information. They sell forecasts at the moment they notice. With the correct information, they can easily predict better product market demand, and in turn, it helps their businesses to scale up their inventory or scale down their inventories. After all, this depends on an immediate requirement.

8. Forecast Your Inventory accurately

Have you heard about the strategy that will forecast your business inventory accurately? Well, this is one of the most crucial for proper inventory management. With proper forecasting, company owners can make informed decisions and several other predictions on every order placement from customers.

9. Use Material Requirements Planning

The particular strategy that entails the usage of computer software and other software apps is to use material requirements planning. This will help you to manage inventory products more easily. Success is also achieved by breaking down the business product requirements into dependent planning periods to ensure the smooth running of every operation concerning inventory.

10. Try Using Batch Tracking

Did you know that batch tracking is one of the feasible strategies for effective stock control system management? They travel along with the distribution chain. This tracking system has been done by using the batch numbers for maximum effectiveness. Furthermore, this shows where goods came from, where they were sent, and the quantity they shipped. If they expire.

By using this inventory data, business owners can better optimize their supply chains and efficiently manage their stock market.

Let’s Talk About The Key Benefits Of An Effective Stock Control System

After thorough research, I have come up with some benefits you can expect to get effective stock control. Below, I will discuss the key benefits of effective stock control.

1. One of the most significant drawbacks that most businesses face is to get out of the stock market. In this case, businesses need to be made aware of the statistics. This leads to quick leverage decisions, which will ensure customers are satisfied. With an effective stock control system, businesses can also have insights into handling a huge amount of stock stored in the warehouse.

2. Cost saving in businesses is closely linked to avoiding understocking and overstocking. A large set of overstocked products would take longer to get sold. With effective business stock management, you can avoid such situations.

3. With effective stock control, there is no requirement to avoid customer disappointment because products are out of stock. Implementing the stock control system also helps you fulfill more orders quickly. This even increases the sales turnover. Moreover, this can eradicate the risk of consumers getting irritated by the long wait.

In Conclusion

I have discussed several strategies for effective stock control management in this article. Stock management is crucial for any business which provides endless benefits. After all, the stock management method will also be the most suitable, and you can appreciate the most advantages by properly incorporating this.

I hope you like this article!

Learn More About: