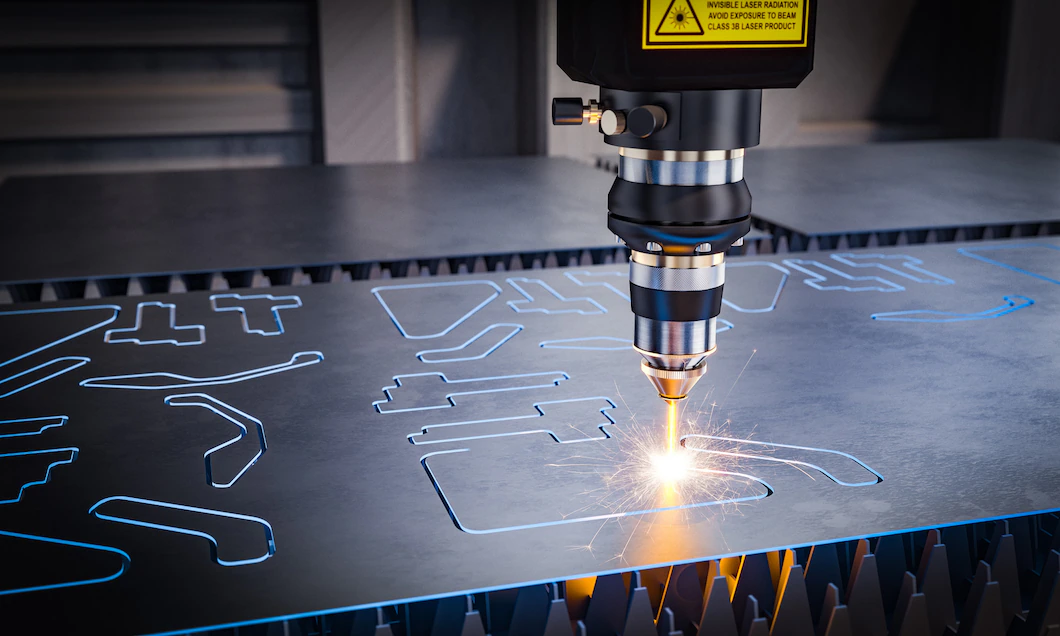

Welcome to the exciting world of laser technology in metal cutting! Cutting-edge lasers are now at the forefront of industry advancements, reshaping the way we slice through metal. No more rough edges or time-consuming operations.

The precision and efficiency these lasers offer are unmatched, making them the go-to metal-cutting tool in various industries. The future of metalwork is here, and it’s brighter (and sharper!) than ever. Read on to learn more!

Beam Steering

Beam steering is like the boss of a laser tool. It tells the laser where to go and what to do. Just as we steer a car to make it go left, right, or straight, beam steering guides the laser beam. This helps the laser make those exact cuts we want.

Without beam steering, a laser tool would be like a car with no steering wheel. It wouldn’t be able to go in a specific direction or make precise cuts.

Rapid Pulse Evolution

Rapid Pulse Evolution, or RPE, is a super cool thing in the world of lasers. Think of it like an upgrade to your laser, making it even better than before. It’s all about controlling the laser’s pulses. With rapid pulse evolution, the laser pulses can be super short or super long, or anywhere in between.

It gives the user more control over how the laser cuts. This allows for faster and more precise cutting, making lasers even more versatile and useful in various industries.

Enhanced Precision Tech

Enhanced Precision Tech is like the superhero upgrade of the laser world, a nifty, super techy addition that amps up the laser’s prowess. It’s all about dialing up precision, making sure the laser is super exact, cutting where you want, how you want. This tech makes lasers a boss, a heavy hitter in various industries, turning the ordinary into extraordinary precision masterpieces.

As technology advances, so does the precision of lasers, and it’s only a matter of time before enhanced precision tech takes us to new heights. So expect even more amazing feats from lasers in the future as enhanced precision tech continues to evolve.

Power Upgrade`

Just like a beast getting stronger, our lasers get a power boost! This is what we call a Power Upgrade. It’s all about making the laser stronger, faster, and better. It’s like feeding the laser a superpower smoothie! With a power upgrade, lasers can slice through tougher metals and do it faster, too.

It’s like going from a bicycle to a race car! Pretty cool, huh? It’s like the cherry on top, making our laser tools even more super-duper awesome. So, buckle up for a wild ride as power upgrades rev up our lasers to full throttle!

Advanced Cooling Systems

Just like superheroes need a chill-out spot after a day of fighting baddies, our lasers need a cool-down too, and that’s where Advanced Cooling Systems step in. Think of it like the laser’s very own superhero lair, keeping the lasers cool and ready for action.

It’s like having an awesome secret weapon that keeps our lasers from needing a nap! This means we can keep cutting and shaping all day, making even more cool stuff. So, just like a superhero needs their secret base, our lasers need Advanced Cooling Systems!

Laser Optics Development

When it comes to laser optics development, it’s all about refinement and innovation. As we continue to push the boundaries of this tech, we’re seeing things like beam steering get more precise, rapid pulse evolution becomes more controlled, and enhanced precision tech delivering tighter tolerances.

Along with this, power upgrades are giving lasers more oomph, and advanced cooling systems are making sure these tools can work longer and harder. It’s a fascinating sector that’s evolving at a rapid pace, constantly delivering new advancements that make lasers more efficient, more powerful, and more versatile.

Intelligent Software Control

Intelligent Software Control is like the brain of a laser tool. It tells the laser what to do and how to act – kind of like how our brain controls our body. It makes big stuff easier and little stuff simpler. It’s like the best video game controller for lasers, helping them do all sorts of neat stuff.

With Intelligent Software Control, we can make lasers do even more cool things, faster and better than ever before. So, it’s important for making our lasers the best they can be.

Laser Cutting Facility

While advancements in laser technology have allowed for greater precision and versatility, one of the key components to utilizing these tools to their full potential is having a modern and well-equipped laser cutting facility. This includes not only top-of-the-line lasers but also advanced software systems, skilled operators, and efficient workflows.

Flexible Fiber Laser Advancements

One of the foremost advancements in advanced laser machining is the development of flexible fiber lasers. These lasers offer unparalleled flexibility and control, making them ideal for handling complex tasks and a variety of materials.

Their flexibility stems from their unique construction, which uses optical fibers to guide the laser beam, providing enhanced precision and adaptability. Advancements in fiber laser technology have also led to increased power outputs and improved cooling systems, enabling longer operation times and greater efficiency.

Integrated Safety Measures

When you’re using a metal cutting tool, being safe is super important. That’s why the Integrated Safety Measures are so cool. They help keep everything running smoothly and make sure nothing bad happens.

So, whether you’re working on a big project or just making something small, you can count on these measures to help keep you safe while you work. And the best part is, they’re part of the tool, so you don’t have to worry about setting them up or anything like that.

Discover The Technology Of Metal Cutting Tool

So, pals, we’ve chatted a lot about this fantastic metal cutting tool, the laser. This superhero tool is not just fast and super accurate, but it can deal with many metals and is always getting better. With all the cool updates coming, lasers are set to rock our world even more.

Did you find this article helpful? Check out the rest of our blog for more!

Read Also: